Valve regulated lead-acid (VRLA) battery is a cycle of charge and discharge battery, featuring without acid water maintenance, battery for sealing structure, which will not leak acid or discharge acid mist, battery lid has a one-way valve (also called safety valve), the function of this valve is to automatically open the one-way valve when the amount of gas inside the battery exceeds a certain value to discharge the gas, and then automatically close to prevent air from entering the battery. This type of battery is generally used as a power source for starting, power, backup, energy storage, marine, automotive, etc., widely used in various aspects of the country's economy and people's lives.

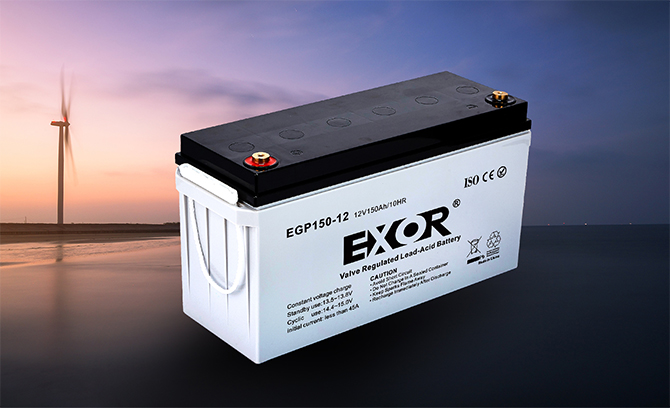

The VRLA rechargeable battery is composed of positive plate, negative plate, separator, electrolyte, plastic tank, connector, pole column, etc. The rated voltage of a single cell is 2V, and a single battery can be composed of several cells in series to form 4V, 6V, 12V and 24V batteries. Its capacity can be as small as 0.3Ah, or as large as thousands of amperes, basically any size can be achieved.

The sealed lead rechargeable batteries are divided into two types: AGM and GEL batteries. Valve regulated AGM battery uses adsorbed glass fiber cotton as the separator, the electrolyte is absorbed in the plate and the separator, poor electro-hydraulic design. There is no flowing electrolyte in the battery. It can work in either vertical or horizontal position; While VRLA GEL type battery SiO2 is used as the coagulant, the electrolyte is absorbed in the plate and the colloid, and generally works in vertical position.

The principle of its chemical reaction is to charge the electrical energy into chemical energy stored in the VRLA lead acid battery, discharge the chemical energy into electrical energy supply to the external system. During the discharge process, the positive electrode active substance lead dioxide of the battery will be converted into lead sulfate, attached to the positive plate, the negative electrode active substance lead is also converted into lead sulfate, attached to the negative plate, while the sulfuric acid in the electrolyte is diffused to the plate, the concentration of the electrolyte is reduced. When the battery is charged, the opposite electrochemical reaction occurs inside the battery. In this way, the regulated lead-acid battery can be used repeatedly until the storage capacity is not up to the requirements of electrical equipment, and its life ends.

After a century of development, the production technology of valve-regulated lead-acid batteries has become saturated. Industry manufacturers basically use this set of mature production process, from the grid, lead powder, paste, coating, chemical conversion, assembly, acid preparation... laboratory, testing to finished products, etc., However, the VRLA battery manufacturers with the development ability often have their own unique design and production process in the aspects of grid, lead paste, acid distribution, battery shell, etc., which will form the design and quality differences of the sealed VRLA battery, thereby forming different market competitive advantages.